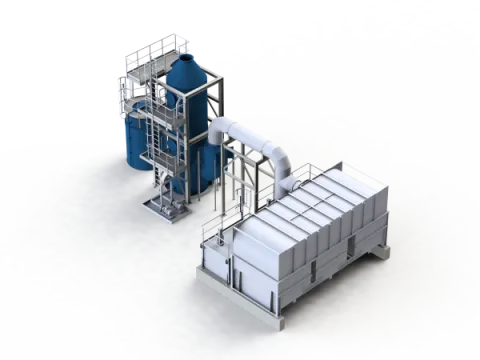

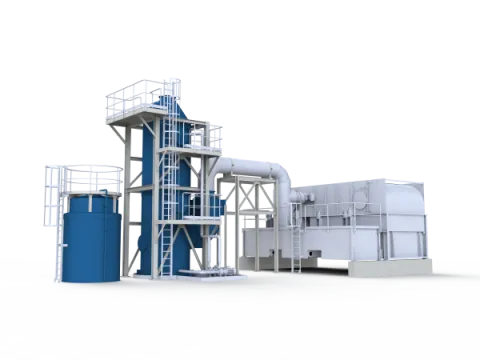

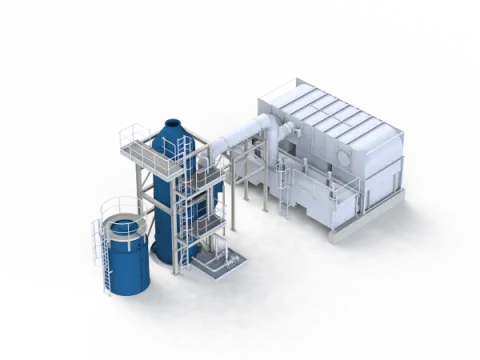

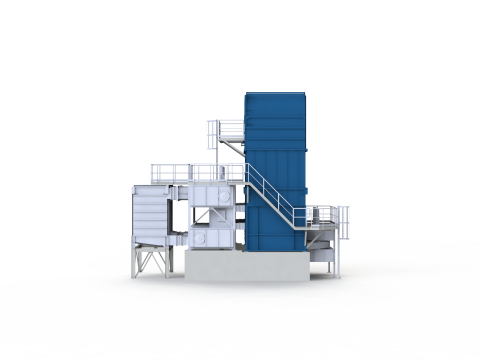

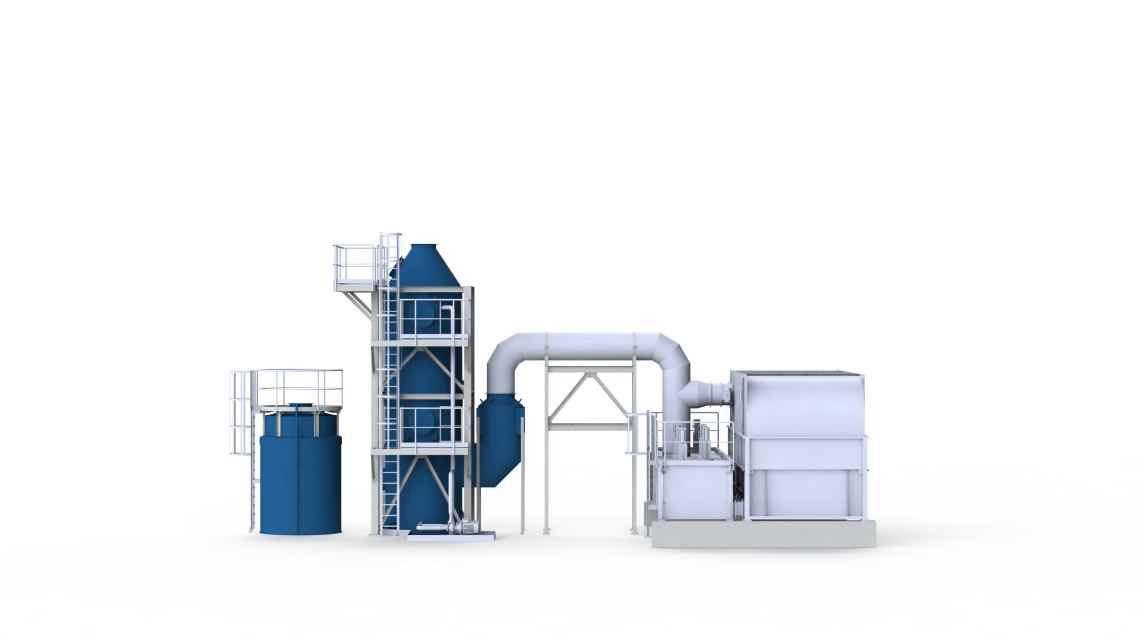

WetSorbTherm

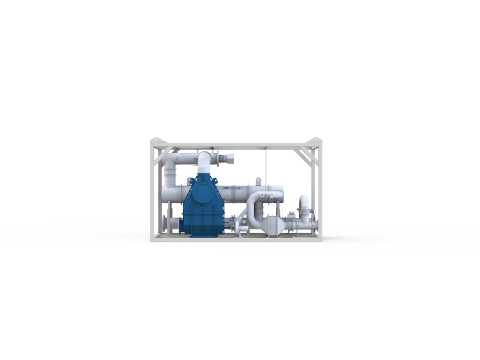

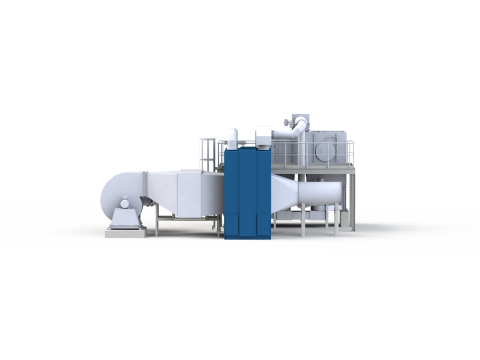

Wet absorber

- Maximum cleaning efficiency

- High safety standard

- High availability

- Low maintenance costs

After the oxidation of for example halogenated hydrocarbons, the corresponding hydrogen halides and elemental halogens emerge. Inorganic pollutants are efficiently removed from the waste gas by wet gas purification.

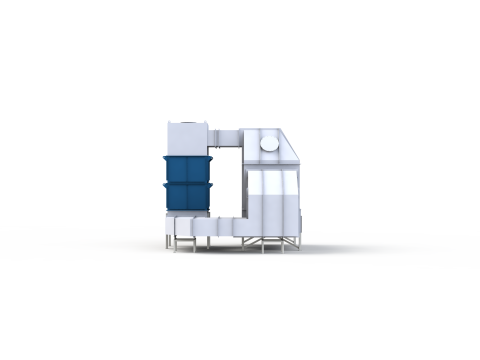

The combination of exhaust gas cooling (quench) and waste gas purification (scrubber) is ideal for use after a convential APC system.

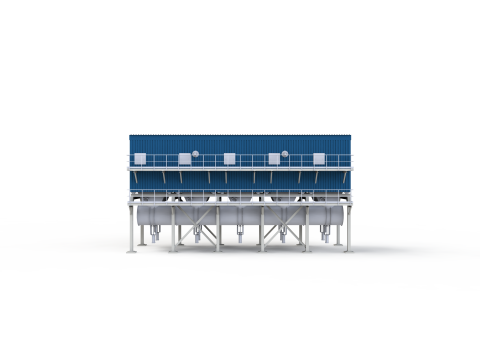

Features

- Maximum cleaning efficiency (>99.5%)

- High safety standard

- Fail-safe PLC

- Selected sensors with SIL classification

- High availability

- Redundant pump system

- Field proven advanced software

- Selective separation of inorganic substances (HCl, Cl2, HBr, BR2, HF, SOx)

- Flexible injection systems for necessary chemicals (supply pipe, lance and nozzles, storage tanks)

- High standardization

- Adaptations for existing, on-site chemical

Available options

- Multiple sensor package for liquid analysis

- Make up water conditioning unit

- Different materials for scrubber (polypropylene, pp reinforced with glass-fibre, reinforced plastic or stainless steel)

- Access platforms

- Plume prevention

Realize your ideas using our products

Are you interested in our products and services?

Do you need more information?

Send us your question or request a call. We are here for you!